DIOSMIN MANUFACTURING

Basic synthesis process

Basic synthesis process

Put hesperidin into a clean,dry reactor, and add a high boiling solvent, remove moisture of hesperdinby means ofdiminished pressure distillation,and then add enough iodine,keeping the temperture properly for several hours , with stirring , in this way crystallization has taken place within a few hours.The mixtures cooled to room temperature,the crude diosmin is centrifuged off, washed with water, dryed、and diosmin is obtained.

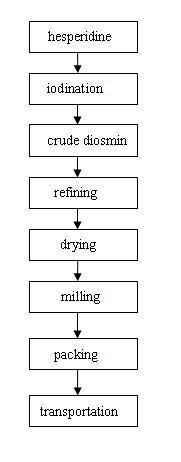

Manufacturing flow chart

Critical control points

Following three critical control points in manufacturing Diosmin are very important:

(1) Quality of Hesperidin – Of course, the quality of main intermdiate is the key point to all products,including Diosmin. The raw material Hesperidin is manufactured by ourselves – we can control the quality as better as possible, and we control cost as less as possible !

(2) Condition of reaction – For chemical synthesis, everyone knows that condition of reaction is the key point for both quality and cost. Thanks our R & D team, the quality of our Diosmin is excellent, completely conforms to the latest edition of European pharmacopeia.

(3) Recycle of Iodine and Pyridine – A better recycle of Iodine and Pyridine means lower residual substances in Diosmin, and a lower waste discharge, it absolutely protects our environment and saves the cost of production.