HESPERIDIN MANUFACTURING

Basic extracting process

Take qualified raw material, dry it in the sunshine, milled, put it into appropriate containers,and add water, get through the steam, boil it for several hours. Then the residue is filtered off, soak it in solution of caustic soda for several hours, filter it again, add solution of hydrochloric acid into the filtrate until solid substances appear. Remove the moisture of the crystal,and pure hesperidin is obtained.

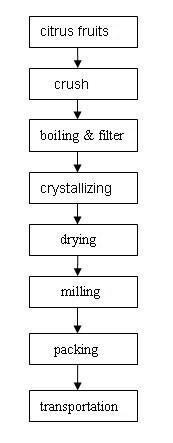

Manufacturing flow chart

Critical control points

In order to control quality and cost of hesperidin, there are three critical control points in manufacturing:

(1) Selecting of raw materials – There are many cultivars of citrus fruits. The raw materials are ok for hesperidin quality in this area today, probably they are not qualified next year.

(2) Absorption – To obtain hesperidin is not difficult, but to control absoprtion of hesperidin as lower as possible is not easy. This is a core specification to reflect the internal quality of Hesperidin.

(3) Control of other citrus bioflavonois – There are many citrus bioflavonoids in citrus fruits except for Hesperidin. Due to their similar physical character, it is hard to control their contents in manufacturing, probably, an integrative utilization is one of best solutions.